This article is also available in Japanese:日本語でも読めます

https://insight.eisnetwork.co/20230607-hydrogen-saf/

- The aviation industry recognizes the urgency to address climate change

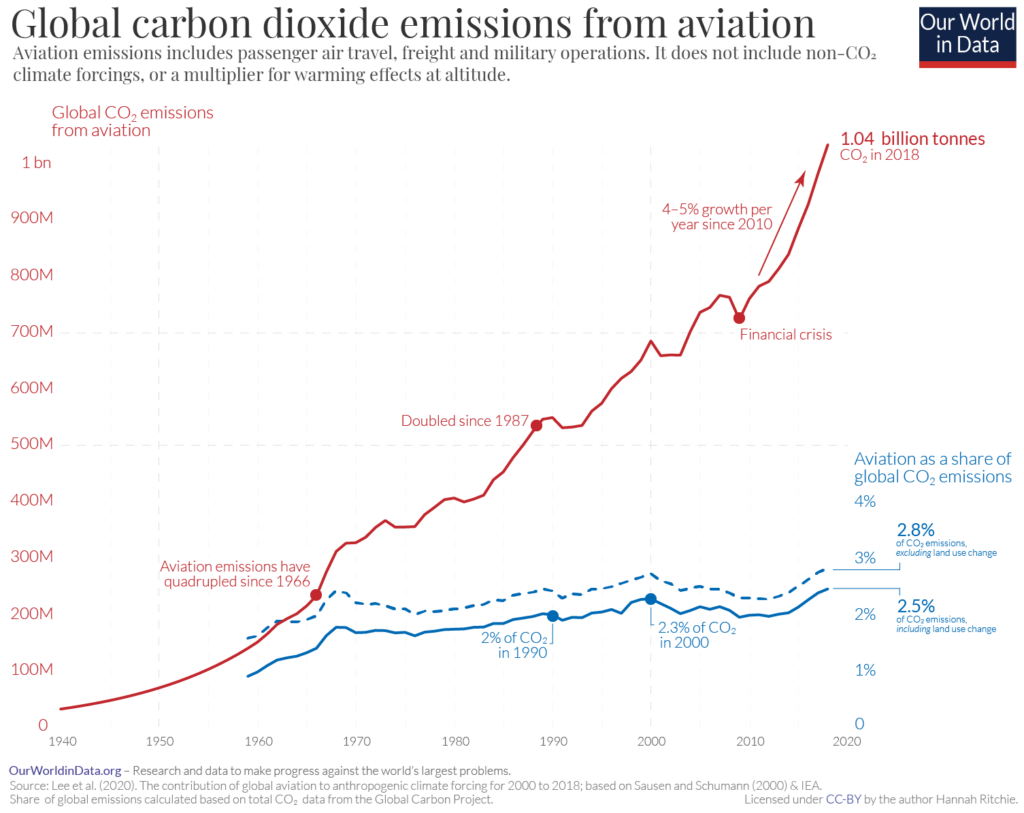

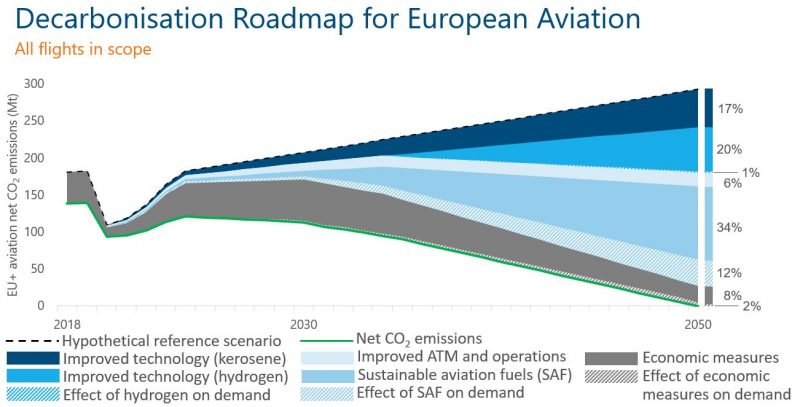

- Air transport currently accounts for ~ 2.5% of global carbon dioxide (CO2) emissions, it needs to undergo a radical transformation. If nothing is done, air transport will account for 9% of CO2 emissions by 2050.

The most promising solutions to decarbonize air transport are using Hydrogen and Sustainable Aviation Fuels.

Hydrogen as a fuel for Aviation

- The aviation industry is increasingly interested in Green hydrogen as a potential solution for the reduction of carbon emissions and the achievement of sustainable air travel. When produced from renewable sources, hydrogen offers the promise of zero-emission flights. It is an attractive alternative to conventional jet fuel due to its high energy density and compatibility with fuel cells or internal combustion engines.

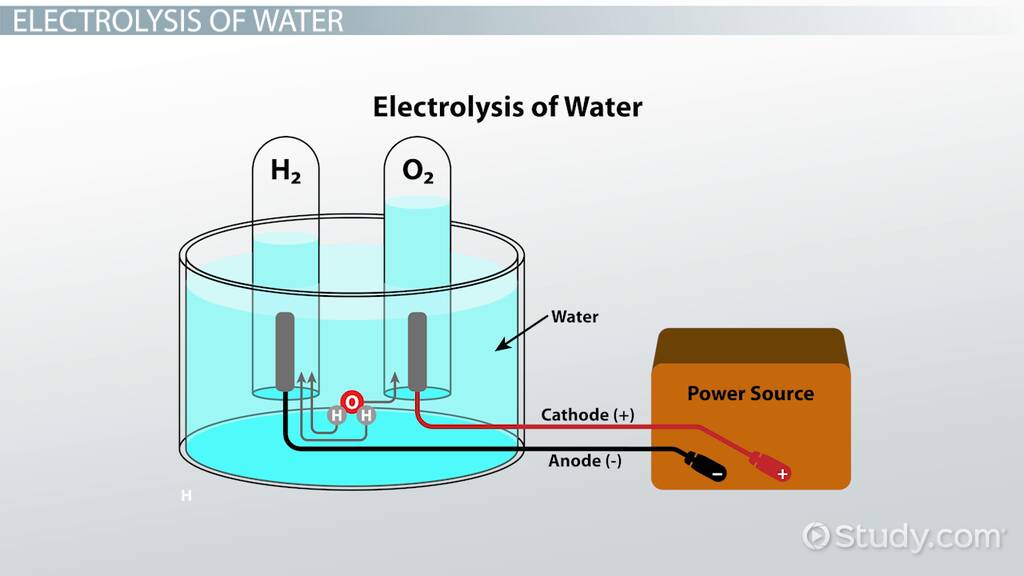

- Green Hydrogen is mostly produced through electrolysis powered by renewable sources like wind or solar. With electrolysis, water is split into hydrogen and oxygen using an electric current.

There are 2 additional ways to produce Green Hydrogen that are still in early stage of development:

- Biomass gasification: Organic matter, such as agricultural waste or wood, is heated to produce a synthesis gas (syngas), which is then separated into hydrogen and other components.

2. Pyrolysis: Organic materials are heated in the absence of oxygen to produce hydrogen, biochar and other by-products. For more on biochar please look at our previous article Reference to biochar article.

Leading players and projects

Aircrafts:

・Airbus:Airbus is at the forefront of research and development into hydrogen-powered aircraft, with the aim of introducing hydrogen as a viable aviation fuel in the future.

・ZeroAvia:The start-up company ZeroAvia is working to develop hydrogen-electric propulsion technology for commercial aircraft and has recently announced the first hydrogen-powered freighter.

・Universal Hydrogen:Universal Hydrogen is also developing hydrogen infrastructure and conversion kits for regional aircraft.

Hydrogen production, storage and distribution:

・Shell:Shell is involved in several hydrogen projects, including hydrogen production from natural gas with carbon capture and storage, and investment in hydrogen refuelling infrastructure.

・Engie:Engie focuses on Green hydrogen production through electrolysis using renewable energy sources.

・Air Liquide / Linde:Air Liquide and Linde are actively involved in the production and distribution of green hydrogen. They are investing in electrolysis technologies powered by renewable energy sources to produce hydrogen without carbon emissions.

Airports:

Airports have been exploring hydrogen. For now activities are mostly focused on production, distribution and usage for ground operations. French airports especially led by Airbus and Air Liquide are very active including Paris, Lyon and Toulouse airports. Other major airports, inc. Changi, Edmonton are also investing.

Government:

The European Union is actively promoting hydrogen as part of its sustainable aviation fuel initiatives and has provided funding for research and development in this area.

Advantages of hydrogen

- Availability of feed stock: the main ingredient for Green H2 apart from electricity is water (electrolysis).

- Hydrogen has a higher mass energy density than fuel. For 1Kg of H2, you will get roughly 3 times as much energy as with traditional Kerosene.

Challenges associated with hydrogen

- Distribution network: Establishing a robust hydrogen distribution infrastructure, including pipelines or refuelling stations, is a complex and expensive endeavour.

- Storage: Hydrogen has a low volumetric energy density which requires efficient storage methods such as cryogenic tanks or solid state storage, which are currently under development.

- Aircraft propulsion and architecture: Hydrogen’s low volume density is a problem that requires a complete rethink of tank location, aircraft architecture and propulsion. For example, ultra-high-security tanks four times the size of those for kerosene would be required.

- Cost: Green H2 is currently about 7 times the price of kerosene. Hydrogen costs about $12/kg, kerosene $0.55/kg and hydrogen has about 3 times the mass energy of kerosene. With improvements in electrolyser technology and the expansion of affordable renewable energy, we should see this gap narrow to almost parity by 2035.

Sustainable Aviation Fuel (SAF)

Sustainable Aviation Fuel (SAF) is a sustainable alternative to conventional jet fuel, produced from renewable resources such as biomass, algae or waste oils.

Demand for SAF is poised to explode. Regulatory incentives, increased corporate sustainability goals and public pressure are driving airlines to adopt SAF to decarbonise their operations.

There are various production methods and feedstock sources for SAF

Hydroprocessed esters and fatty acids (HEFA): HEFA is currently the most widely used method of producing SAF. It involves the conversion of vegetable oils and animal fats into jet fuel through a process called hydroprocessing.

Biomass-to-Liquid (BTL) : BTL involves converting biomass, such as wood chips or agricultural waste, into a synthetic crude oil through a gasification process. The crude oil is then refined to produce SAF. BTL is the second largest process currently used.

Power-to-Liquid (PtL): PTL uses an electrochemical process to convert carbon dioxide and water into hydrogen, which is then combined with carbon dioxide to produce a liquid fuel. This process is upcoming and is getting a lot of attention.

・Alcohol-to-Jet (ATJ): ATJ involves the conversion of ethanol or butanol into jet fuel. It is competing with existing usages of ethanol.

Algae-based: Algae can be used to produce SAF through genetic engineering. This process is still immature but Euglena, a Japanese company, is pursuing this route.

Leading players and projects

Airlines: United Airlines aims to purchase 1.5 billion litres of SAF over the next 20 years.

Energy companies: Neste (FI) is the largest producer of SAF primarily focusing on HEFA and ATJ.

Airports: Schiphol Airport has set a target of using 14% SAF by 2030.

Advantages of SAF

- SAF can be used in existing aircraft, at the cost of a few engine adaptations. Flights using 100% SAF fuel have already been made on jet and turboprop aircraft.

- SAF relies primarily on the same infrastructure for the distribution which would require limited adaptation across the value chain.

- Potential for gradual implementation: SAF is mixed with non renewable fuels (kerosene) and can be gradually added to the mix.

Challenges

- Feedstock availability: by 2050, France alone will need 6 million tonnes of SAF for its own air transport needs. However, used oils (HEFA) will not be able to supply more than 4% of the requirement, and forestry and agricultural residues (BTL) no more than 20%.

- Cost: Like Hydrogen, SAF production is still economically challenging vs. existing non renewable fuels…

Pros and Cons

Comparison of hydrogen and sustainable aviation fuel in terms of their technical feasibility, environmental impact, infrastructure requirements, and economic viability.

- Potential for reducing carbon emissions and the compatibility of each technology with existing aircraft and engines.

- Potential for cost competitiveness and scalability of both technologies.

- Safety concerns or regulatory considerations associated with each technology.

EIS Insight

The Need for Both Technologies

- Both technologies have unique advantages and can complement each other in achieving decarbonization goals.

- Given the hurdle, there will be a need to pursue both technologies and they will coexist.

- The development will follow a phased approach, where sustainable aviation fuel can be used as an immediate solution while hydrogen technology continues to develop.

- Power to Liquid (PtL), a new SAF production technology from Hydrogen represents a significant opportunity for the industry to pursue both directions