This article is also available in Japanese:日本語でも読めます

A sustainable method of producing animal feed that is gaining popularity around the world is upcycling organic waste with Black Soldier Fly larvae (BSFL). The black soldier fly is a fly species that can consume large amounts of organic waste and convert it into protein-rich animal feed. This process of using black soldier fly larvae to convert organic waste into animal feed is called “upcycling”, turning waste into a valuable resource.

Containing up to 42% protein and high levels of essential amino acids, black soldier fly larvae are a highly nutritious and sustainable source of protein. This makes it an ideal source of protein for livestock in areas where traditional protein sources such as soybean meal or fishmeal are expensive or not readily available, but more importantly as a way to reduce the carbon footprint of livestock.

How does the process work?

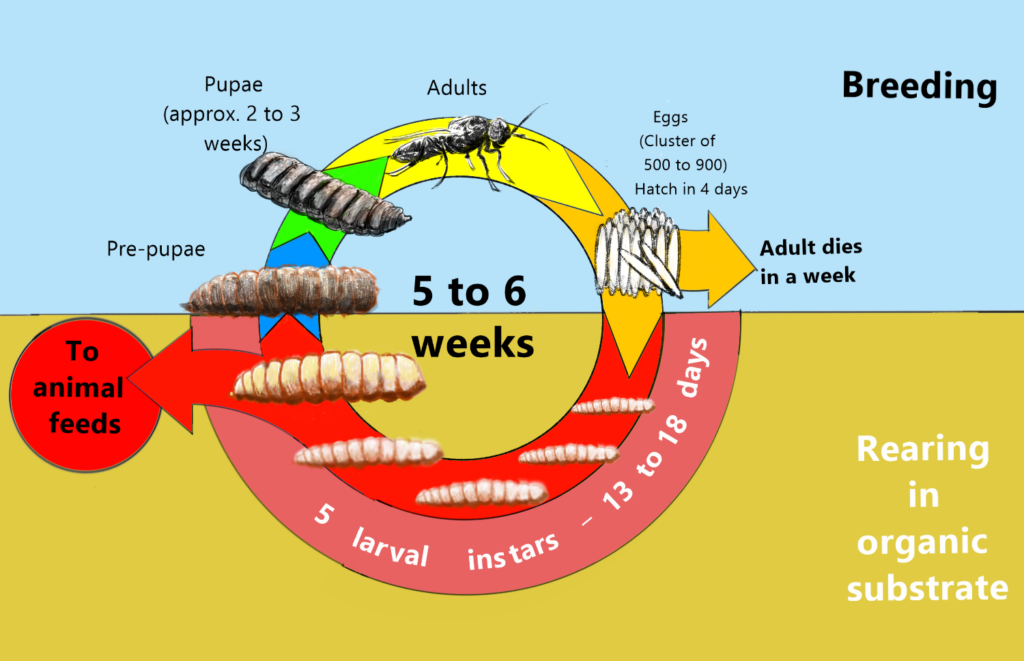

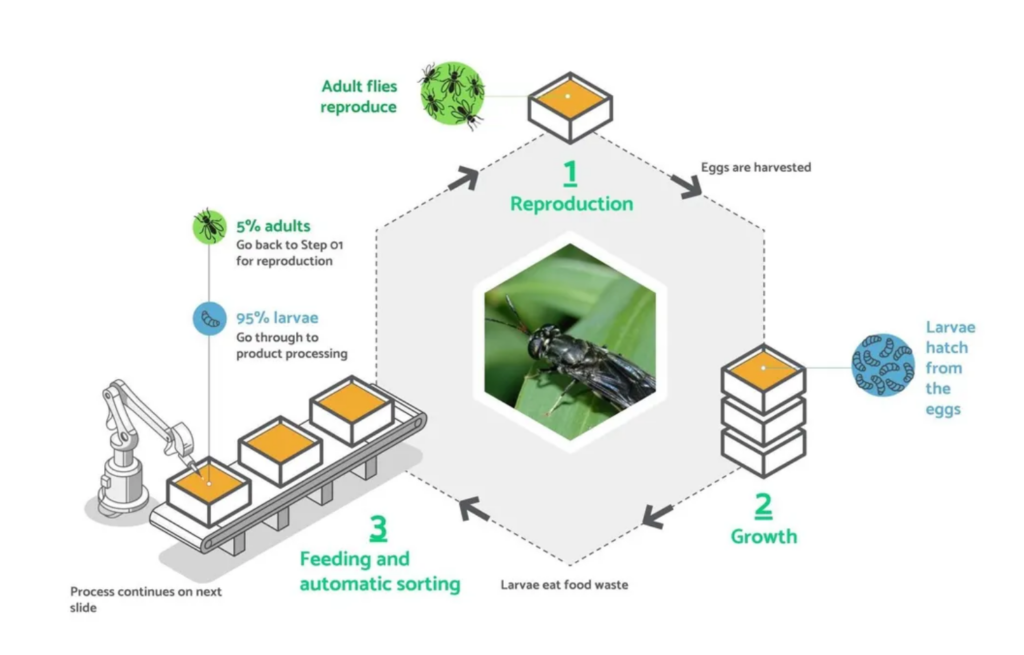

The larvae can be raised on a variety of organic waste materials, including food waste, manure, and other agricultural byproducts. As the larvae consume the waste, they grow rapidly and accumulate large amounts of protein and fat, making them an excellent source of nutrition for animals.

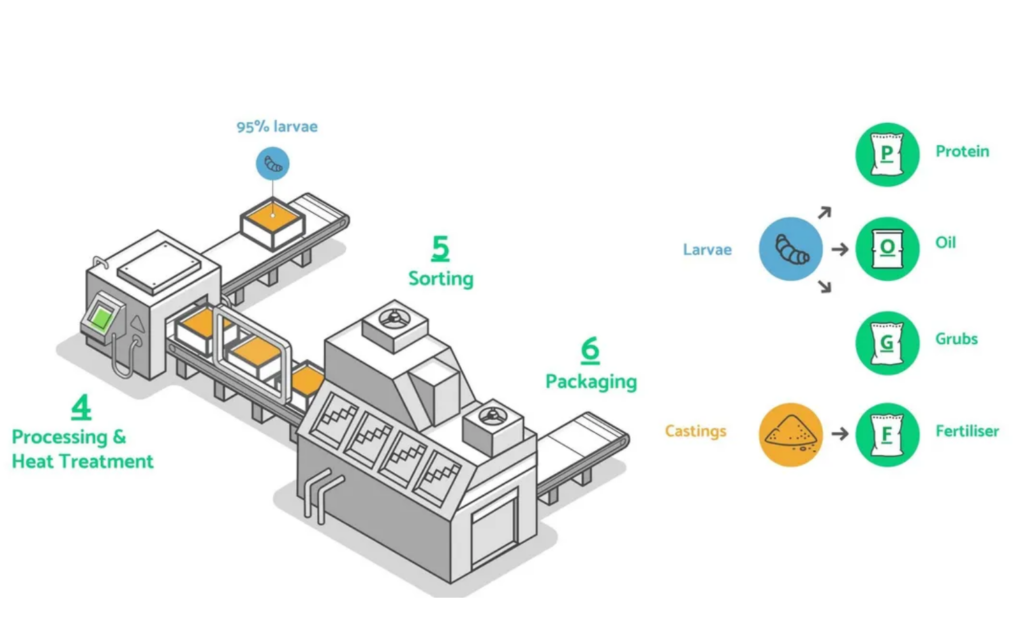

Once the larvae have matured, they can be harvested and fed directly to animals such as chickens, pigs, and fish. The larvae can also be processed into a protein-rich meal that can be used in animal feed formulations. This reduces the need for traditional animal feed ingredients like soybean meal.

BSFL is produced around the globe. The required processes and technologies differ greatly from one place to another depending on the local climate, the scale of the plant, and the usage of the feed. The common foundation is access to an affordable substrate for the BSFL to fee onto. In most cases, sizable amounts of byproduct / organic waste / are from agribusinesses.

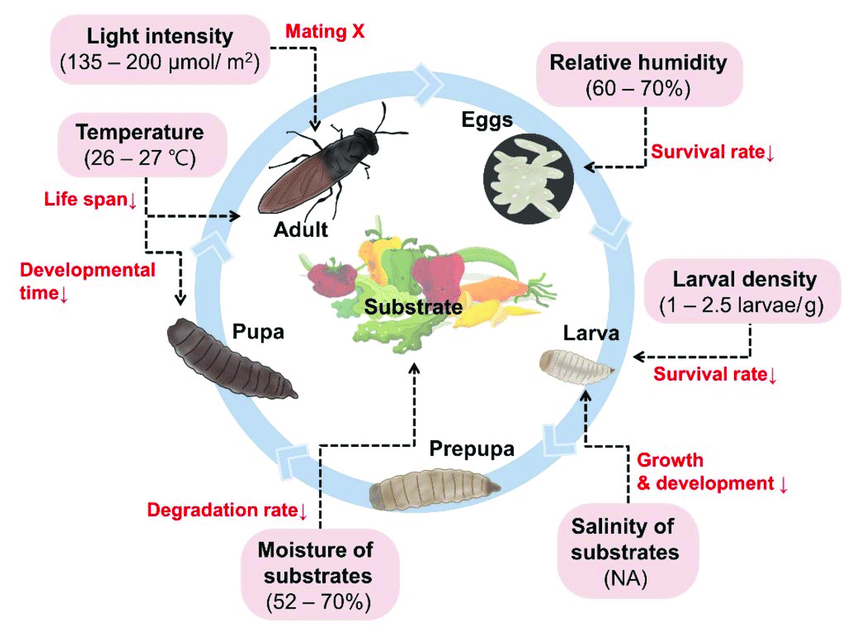

Beyond substrate below are some of the variables that influence the quality of the product value, production processes, costs, and scalability.

- Environment: BSFL can be grown in different production systems such as indoor, outdoor, and semi-indoor.

- Temperature: The optimum temperature range for BSFL growth is between 20-30°C, which is the natural temperature in parts of Africa. In other places (Europe, the USA, etc.) the temperature can be controlled by heaters, fans, and air conditioning.

- Lighting: light stimulates larval feeding behavior, increases growth rate, and synchronizes developmental stages.

- Automation: Automated systems can be used to control and monitor the various parameters mentioned above.

- Value addition: The harvested larvae can be processed into different forms such as meal, pellets, or a freeze-dried powder.

- Quality: The quality of the BSFL feed can be monitored by using sensors to optimize the parameters (e.g. nutritional content, microbial load, presence of harmful contaminants, etc). The quality dictates the potential usage of the BSFL feed (from poultry, and fish to humans) and therefore its value.

Startups involved in the development of the industry

The industry is booming and there are many startups involved in the production of Black Soldier Fly based feed. The models and investments differ greatly by geography.

Europe, US, East Asia

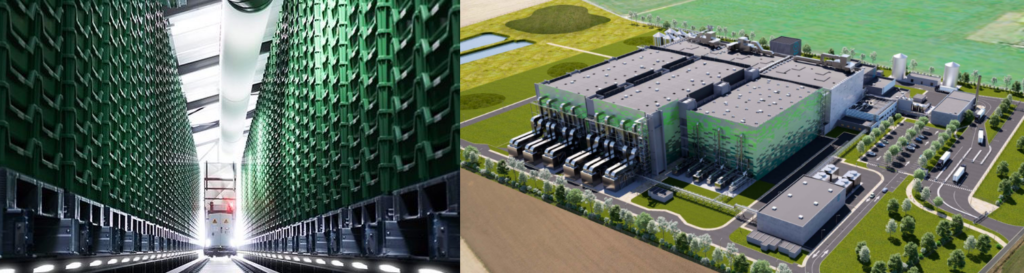

In developed economies, the models are significantly more technologically oriented to cope with environmental conditions but also to reduce labor cost.

Ynsect is a French company that has developed a vertical farming system for Black Soldier Fly larvae to produce high-quality insect-based protein for animal feed and pet food. They have raised over 400M$ to develop their model and the largest BSFL farm worldwide outside of Paris.

To ensure the availability of substrate, they have developed a close relationship with several agribusinesses, including the sugar industry to offtake their beetroot, and secure the feed in line with their scale and planned development.

Another interesting model is Hexafly. This Irish start-up, although earlier in its development, has also clearly understood the importance of a sustainable feed source. Their industrial process uses Black Soldier Fly larvae to upcycle brewery waste into high-quality protein for use in animal feed and aquaculture.

Other notable startups include, Innovafeed (FR, 422M$ funding), AgriProtein (UK, 122M$ funding) or Nutrition Technologies (Malaysia, 34M$ funding including Sumitomo Corporation).

Africa

In Africa, the models tend to be much smaller scale, more labor intensive with limited automation, and lower CAPEX on environment control as many parts of Africa offer the perfect natural environment for the larvaes to grow. The main requirement in Africa is the aggregation of biowaste (substrate) as agriculture is more fragmented with the majority of the farmers owning less than 2 acres.

InsectiPro in Kenya has for instance developed a franchising model to quickly replicate their model and empower smaller units to be deployed where waste can be aggregated. The company is supported by the Bill & Melinda Gates Foundation (2M$ funding) and has become one of the leading models in Kenya.

Even at small scale, waste aggregation remains critical to provide the feedstock for the BSFL farms.

Kisii Smart Community, one of the EIS social ventures developed with support from the Toyota Mobility Foundation, has created such a logistics platform to aggregate bio-waste from small farmers and markets in Kisii to support a local franchise following the InsectiPro model. (link)

Another interesting startup in Kenya is Regen Organics, a daughter company of Sanergy. Sanergy is a social enterprise founded in 2011 and based in Nairobi, Kenya. The company’s primary focus is to improve sanitation in urban slums in Kenya and other parts of Africa. Sanergy has developed sanitation facilities called “Fresh Life Toilets” and collects the waste from the toilets, which is then used to feed the larvae.

Given the low level of infrastructure needed in Africa, the model has spread across the continent. Other notable startups are: BugLife (South Africa), BioLoop (Nigeria), Farmster (Ghana), and BioButz (Tanzania).

EIS Insight

BLSF represents a significant opportunity to produce protein for animal feed or human consumption.

The main issue for its development is the competitive use of bio-waste with other activities (e.g. biofuel, SAF, biochar, etc.), especially in developed countries.

In these regions, captive systems with organic waste producers, such as breweries or sugar factories, with long-term feedstock contracts should be quickly established for players in this field, especially given the scale of the projects they are pursuing.

The higher costs of inputs, labor and hardware need to be offset by added value. Consistent and superior quality from the controlled environment and automation allows BLSF to move into higher value-added products such as human consumption.

In Africa, BLSF will be more labor intensive, produce lower quality outputs and be more fragmented. Aggregating these distributed resources will also make the model more resilient, and projects such as EIS’s Kisii Smart Community will help address this issue.